PRODUCTION PICKING LIST

1. Purpose

It was used to pick materials up and transfer them to the manufacturing plant where the products were created.

2. Link

Manufacturing Management→ Process implementation → process board

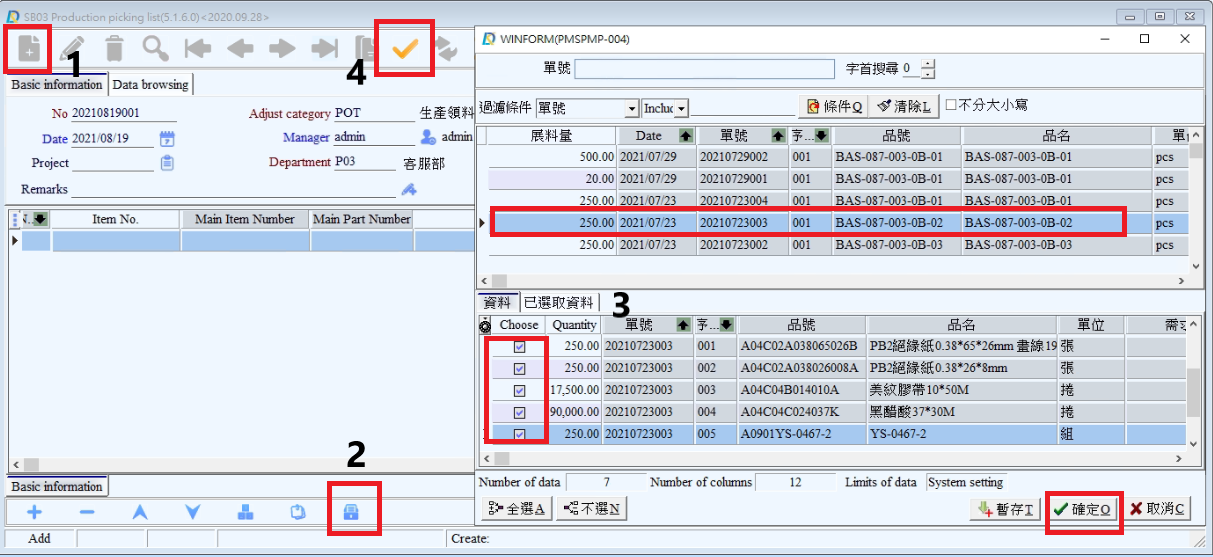

3. Basic information images

XXX (Basic information picture)

● Number: The code number of list. When setting up input- output intentory parameter, if order number is set by [Manually code] typing, it would be input by the current user. On the other hand, if it is set by「Day code」, it would be show up by itself. It can not be left blank.

● Date: The system will automatically display the current date of the system, no need to manually type. You can also modify it by yourself, it can not be left blank.

● Project: Project of the sale order.

● Department: Enten the department

● Process code name: From SA01

● Adjust category: you can enter adjust category here or it can be left blank

● Property: Selecting the basic properties of the order for more quickly looking up the relevant order later, you can click to open the "Properties" window to select it, It can be left blank.

● Manager: The current user

● Remarks: emarks: You can enter the content of the note here or click the icon to open a search window "Common Remark" or it can be left blank.

XXX (Body part picture)

● Ordinal number: The system will set automatically

● Item code number: You can enter the minor item by clicking "Get an order" button to open window for take the sale order.

● Main item number: The main product code name

● Main part number: The number of main product

● Name: Full name of minor part.

● Unit: The unit of weight of minor item

● Warehouse code: Code name of warehouse

● Quantity: The quantity of products in sale order

● Source list: it was linked

● Remarks: You can enter the content of the note here.

4. The step of process

(1) Click on「Add」icon。

(2) Click on "Get an order" button to open window for take the sale order.

(3) Choose the materials would be processed and click “Accept” button.

(4) Click “Save” icon for completion.